Thermal Insulation

Acoustic Treatment

PROJETO COCO VERDE

GREEN COCONUT PROJECT

Reaction to fire:

Self-extinguishing

Radical Innovation

The most important concept of sustainable consumption and ecological consumption, on a GLOBAL LEVEL, is the choice of all the materials that will make up the construction of some property and the destination of these materials when this property is dismantled.

This is ecological thinking.

Resistance test of our products

Naturally self-extinguishing in fire

Technical Information

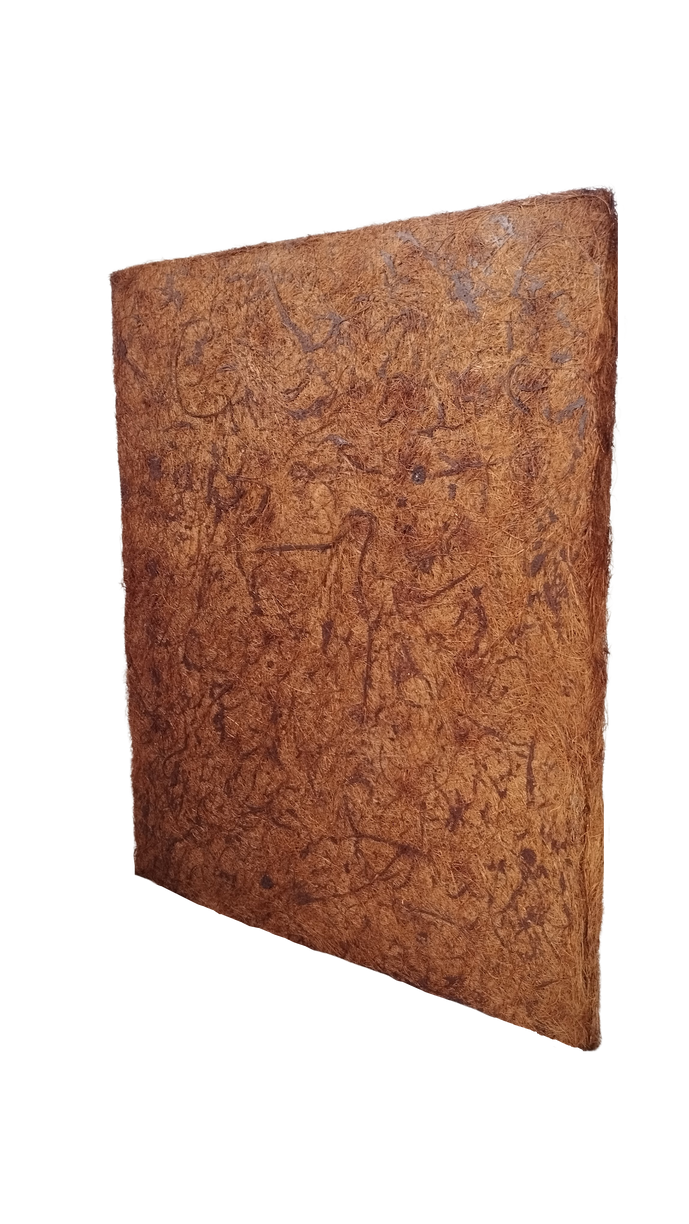

Dimensions:

500 x 600 x 30 mm

1000 x 990x 30 mm

Coefficient of Sound Absorption:

0,65(H)

Coefficient of Thermal Transmittance:

0.053 W/(mºK)

Coeficiente de Absorção Sonora:

0,65(H)

Get to know COCUS NOISE REDUCTION

In addition, the Green Coconut Project's coconut fiber boards are the only ones on the global market with the following features:

- Product 100% natural and ecological (raw material RENEWABLE SOURCE);

- 100% reusable without the need to recycle; It will never be GARBAGE;

- With our technology, in addition to plates, it is possible to obtain concave, convex, and spherical formats, formats that increase sound absorption. It will be useful for architects and decorators because it increases the aesthetic possibilities and guarantees sound quality;

- Coconut fiber, unlike synthetic and other natural products that are not ecological, will need to find a final destination after its use, which will entail high costs;

- It withstands high temperature ranges;

- In case of fire, it does not release toxic gases;

- Water resistant (in case of infiltrations); Permeable to water vapor avoiding condensation;

- Biodegradable;

- Odorless;

- Does not release solvents or dangerous particles, is imputrescible and unassailable to insects and rodents;

- Good dielectric characteristics, originating less electrostatic charges than synthetic insulators;

- After use, totally reusable for acoustic treatment or thermal insulation, or in other diverse horticultural applications;

- It is a product that follows the ESG pillars, as well as the good practices of the 5Rs (Reduce, Recycle, Reuse, and Rethink);

- It is sold with natural pigmentation and no synthetic pigments are used.

The COCUS NOISE REDUCTION is an innovative and environmentally friendly acoustic material made from coconut fiber that offers a number of benefits for various applications.

With a controllable density, it is a perfect material for acoustic absorption and thermal insulation.

It has a lifespan of over 100 years, easy installation, water resistance, insect protection, and biodegradable properties that make it an ideal choice for a wide range of projects.

With its natural, renewable, and biodegradable properties, COCUS is perfect for those who want to create a sustainable and healthy living environment.

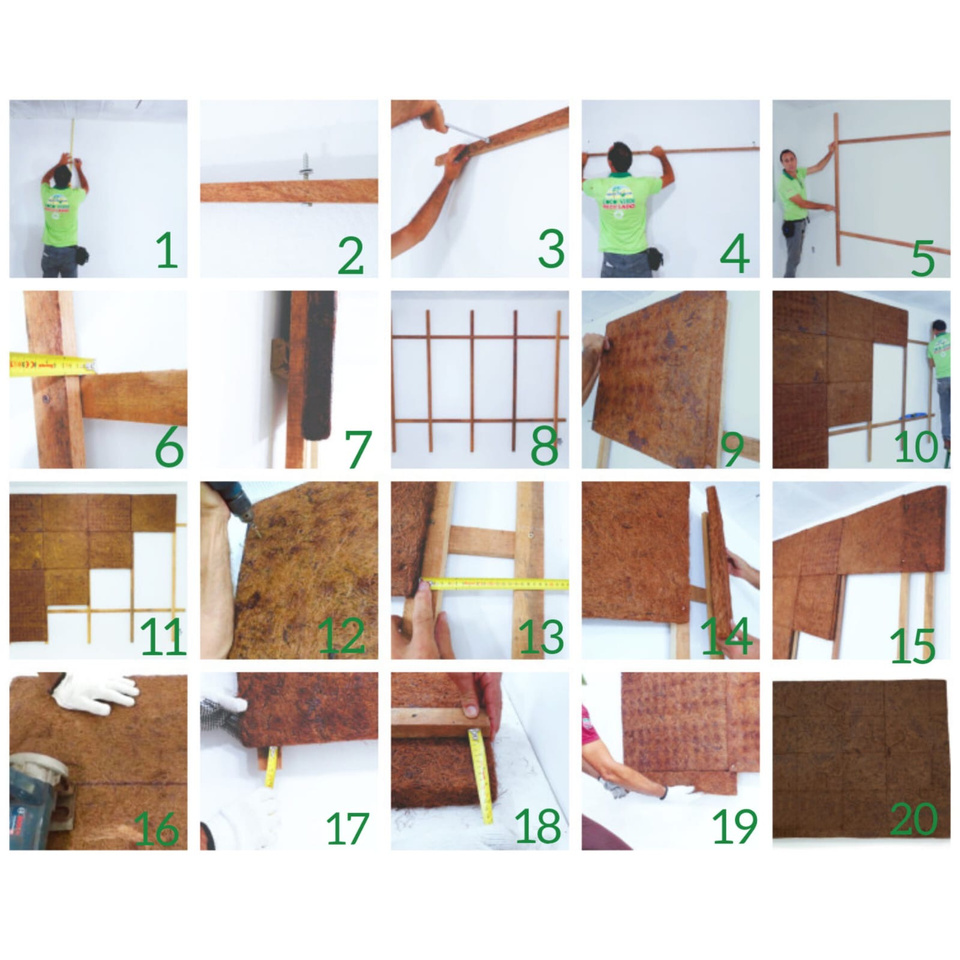

Suggested Plate Installation

STAGES 1, 2, 3, 4: Place the two wooden structures that will support the entire panel horizontally.

ATTENTION: Use aluminum washers in the four fixing holes so that the wood does not have direct contact with the wall (Image 2).

STEPS 5 and 6: Fastening the vertical wood crossbars to the horizontal ones previously installed, using self-tapping screws to make the whole assembly easier and faster.

STEP 7: Application of the coconut fiber board that will be 5 cm from the wall.

STEP 8: Structure that will support the coconut fiber boards is finished.

STEPS 9,10,11,12: Fastening the boards to the wooden structure, also using the self-tapping screw.

STEPS 13,14,15,16,17,18 and19: If necessary, cut the coconut fiber boards on site to fit the size of your panel. No special protective equipment is required, as it does not generate toxic residues.

You can use the in natura finish or request a fabric finish.

In this example of 5.4 m2 only 4 holes were used in the wall, without glue or any other material that would damage your property.

STEP 20: In this example of 5.4 m2, only 4 holes were used in the wall, without glue or any other material that would damage your property.

RECYCLED GREEN COCONUT. We are also known as the Green Coconut Project. In the dynamics of every industry, every fifty or a hundred years, what is conventionally called a "PARADIGM BREAK" occurs. For it is precisely this type of irreversible change from a new technology in the manufacturing of coconut fiber products. We hold a new innovative (Radical) technology to manufacture coconut fiber products for the most diverse sectors, and have been granted an Invention Patent (IP). Coconut fiber is believed to be one of mankind's oldest raw materials.

Globally we are pioneers in green coconut recycling.

"Truly Ecological Noise Reduction"

For us, coconut waste is an example of sustainability.

Economically viable.

Socially fair.

ecologically friendly.

Our Radical Innovation

Our products use as raw material coconut fiber agglutinated with a mix of plant extracts, all of them extracted from reforestation, thus all from renewable sources.

We do not generate any type of waste during the entire production process of our raw materials and in the very process of manufacturing the coconut fiber in various products.

Our activity consists in manufacturing coconut fiber, transforming it into various products that serve the most varied sectors, from gardening to civil construction.

This is a project that is not limited to a specific geographical region (scalable), and can be implemented in any country.

There are more than 300 models of artifacts made of coconut fiber with applications for plants in general, a wide range of cache pots, vertical gardens, aquarium, terrarium, tutors for philodendrons, floral design, artistic design, green roofs, products for corporate gifts, acoustic treatment, thermal insulation, evaporators for civil construction, filters, partitions, grass limiters, evaporative cells, germination plates, a wide range of supports for hot and cold containers, among others. Its characteristics make it, in general, an artifact of multiple use.

sac@projetococoverde.com.br

@cocoverdecomunicacao

+55 21 3356-1030

Philippe Jean Henri Mayer

Researcher|Pesquisador

philippemayer@gmail.com

Philippe Jean Henri mayer

(55) 21 9 8272 0691

Philippe Jean Henri mayer

In this site we do not intend to explain about the theme. We do intend to present a new product that is appropriate for the times in which we live, and not products that harm the environment.

Respecting the proper proportions, we can make a simple comparison between our industry and a car factory with its dealerships.

We look for partnerships to build our network of dealerships and not with the final consumer.

These should be able to supply all the needs of the market around them.

To demonstrate the versatility of our innovative technology, here are two images showing a 100 x 99 x 3 cm coconut fiber board on which 3 convex artifacts (fiber) were fixed and decorated with artificial plants. Creation of a vertical acoustic garden.